Services

Offering industrial design, mechanical engineering, prototyping & testing, molds & dies, production & assembling,

and supply chain management services for end-to-end manufacturing solutions.

INDUSTRIAL DESIGN

At ALPHA, we use Industrial Design to create innovative products that put the user first. Balancing project goals, budgets, and the user’s needs, we strive to create real world solutions that are as functional as they are beautiful. Our process is iterative, exploring many concepts through sketching, 3D CAD modeling, and quick mockups, as we progressively refine down to a single executable design.

Iterative Approach

Our iterative design development process starts big and filters down to a final design, collaborating with our clients as we go. Rooted in sketching, our preliminary concept work combines preliminary user research, project must have features, and aesthetic treatments to provide thoughtful solutions in a visual form. Based on client selections, we refine our designs by applying different lenses to the project, resulting in an appealing and executable design.

User Journey

Our user centered design approach insures we are meeting and exceeding the needs of the user. Mapping the user journey of a product reveals user interface challenges and opportunities for design intervention that drive design decisions and create intuitive and optimized consumer products.

Ergonomic Considerations

We use ergonomic data to make informed decisions when it comes to how users will interact with our designs. This data enables us to design to the human body and has influenced touch points, reduced fatigue associated with repetitive movements, and improved performance attributes and over-all functionality for every product.

Quick Turn Mockups

Cardboard sheets, foam, 3D printing, and disassembled product components are all resources we use to make rough, quick turn mockups that can be used to easily and quickly evaluate ideas during the Industrial Design process. This prototyping process also improves our general understanding of scale, volume and user interface constraints. We strive to test multiple ideas up front to insure we don’t exhaust precious time and money on solutions that fall flat early in the process.

Concept Development

Starting with sketching to quickly assess ideas, we work through various designs until we find a solution that fits each project’s much have requirements and user needs. We find inspiration in other products, environments, and from our own personal experiences that allows us to utilize different technologies, experiences, and forms in new ways.

MECHANICAL ENGINEERING

Mechanical engineering bridges conceptual ideas with the real world. Taking designs from the industrial design phase and putting them into 3D CAD models progresses projects forward toward a physical, testable sample. During the engineering phase we design and audit solutions for a product’s construction, structural requirements, manufacturing, ease of assembly, and form integration. Our goal is to insure that we are building manufacturable products that will be high quality, fully functional, durable, and beautiful.

3D CAD Modeling

3D CAD Modeling applies definition and dimensions to sketch concepts. We use the latest version of Solidworks to bring concepts into a 3 dimensional format, providing the necessary information to build parts that are accurate and to scale. We also utilize Solidworks Simulation to run FEA analysis, assessing the physical strengths and weaknesses of our designs in safety and high load applications.

Component Integration

We understand that bringing products to market can be expensive so we strive to reduce costs through optimization of component count and streamlined assembly. Where possible, ALPHA utilizes OEM components to save on tooling costs and to increase speed to market.

Design for Manufacturability and Assembly

Our goal is to design and engineer products for the real world. That means our designs need to be manufacturable. We audit every design throughout the product development process to insure we meet manufacturing and tooling constraints, budgetary requirements, and avoid expensive mistakes in mass production.

Material and Process Selection

Our team has a vast knowledge of both material science and manufacturing processes. We make every effort to properly align your product’s cost of goods with the materials and manufacturing process to meet your design’s functional requirements.

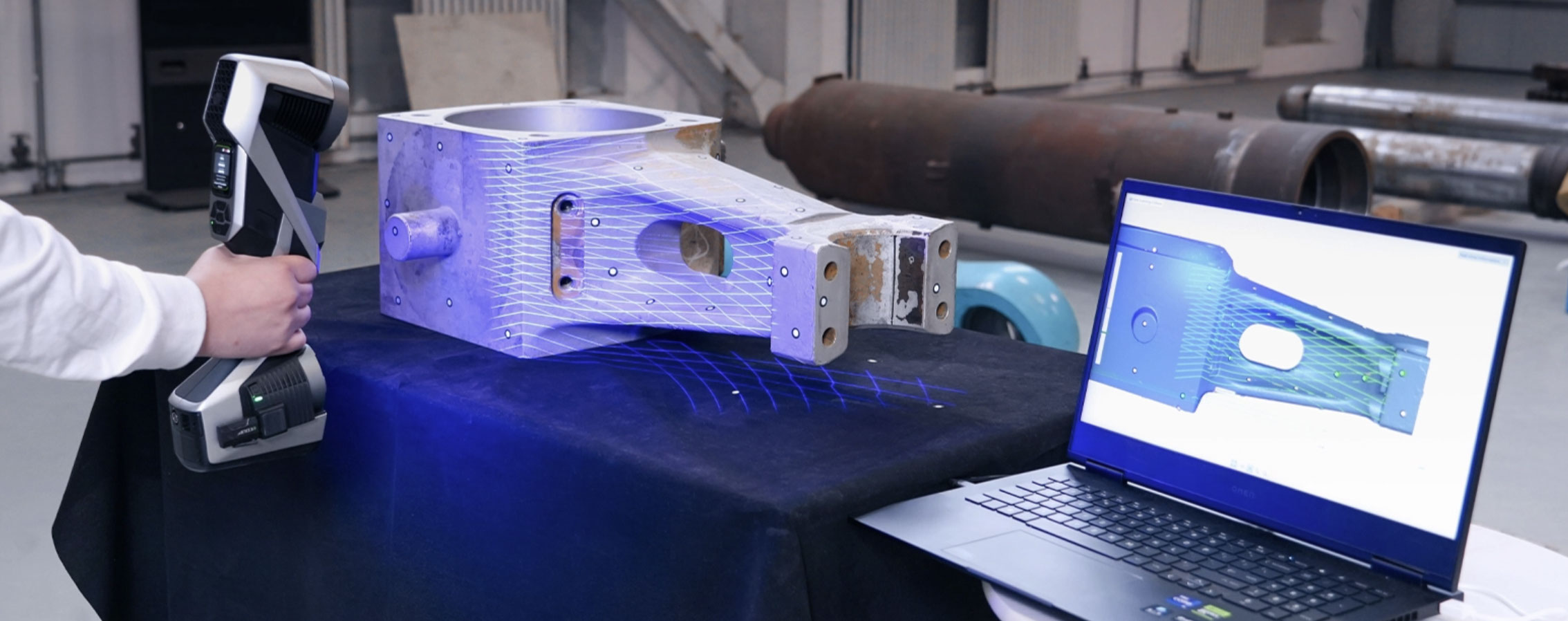

PROTOTYPING & TESTING

At ALPHA Product Design, we advocate for bringing ideas into the real world as soon as possible. Prototyping is a great and fast way to evaluate the potential of your product idea without committing to production. We offer multiple types of prototypes, ranging from simple hand built mock-ups to fully functional assemblies that can be field tested and photographed.

General Prototyping Services

RTV Silicone Vacuum Casting / Custom Painting and Finiishing / CNC Machining and Turning / Hand Built Mockups / 3D Printing Prototypes / Prototyping Molds and Sampling

Testing and Refinement

We create prototypes that can be used in preliminary testing to verify strength and functionality. Multiple rounds of iterative prototypes are often used to refine and optimize designs before committing too expensive production tooling.

Prototyping Constraints

Prototyping comes with a unique set of material and process constraints. Once we understand the functionality requirements of your product, we look at optimal material choices for both prototype and production development. We will do our best to closely match prototype parts with the characteristics of subsequent production parts, providing a close match to undergo testing and performance analysis.

Assembly

Our prototypes are constructed from parts made by different suppliers that undergo assembly in our studio to insure proper fit and function. We use the initial build to understand manufacturing and assembly complexities that may have been overlooked during the design and engineering process, helping us better prepare for production.

Small Batch Pilot Production and Prototyping

Once the initial prototype is produced and approved, additional prototypes can increase the opportunity for testing and refinement among a larger group of users. When requested, ALPHA has delivered small batches of prototypes to clients looking to gather more feedback. Additional prototypes can also be used in sales and marketing samples, to gain upper management approval, and to provide a tangible sample to help visualize the product idea.

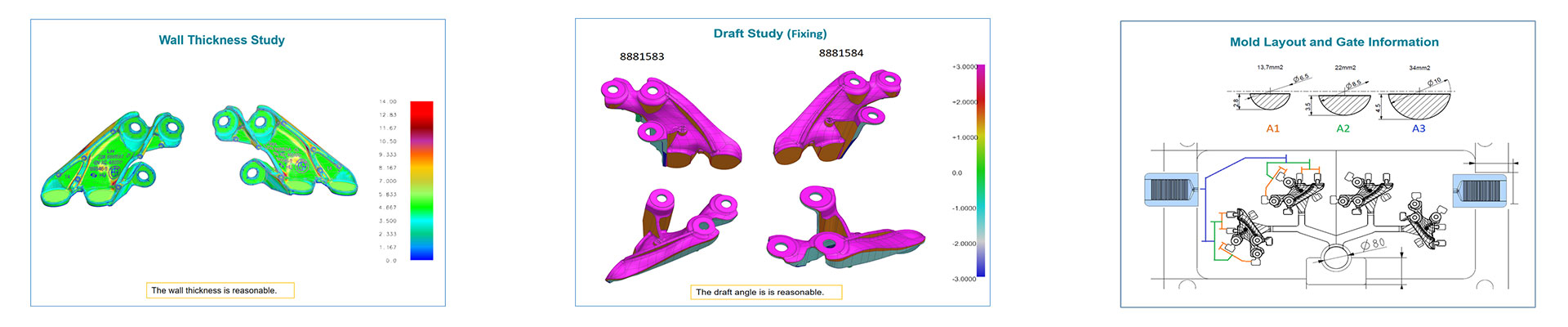

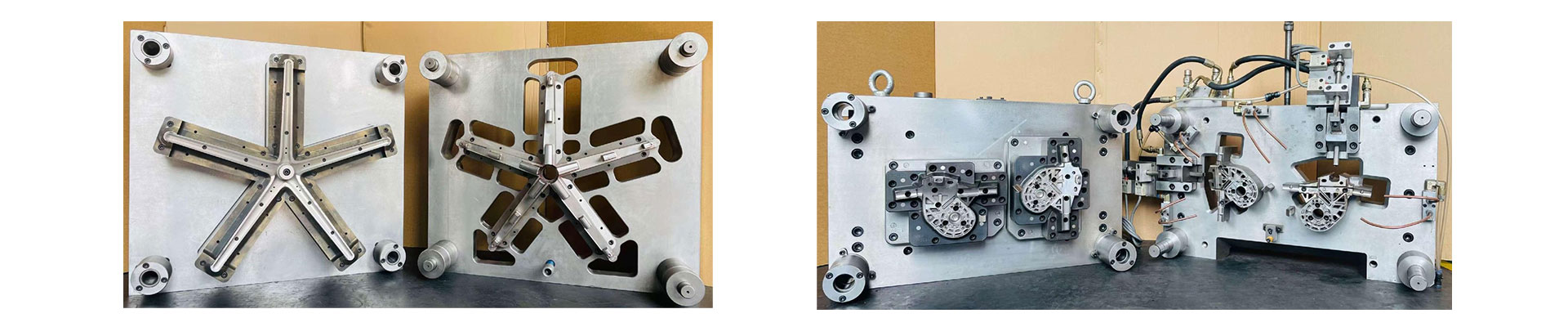

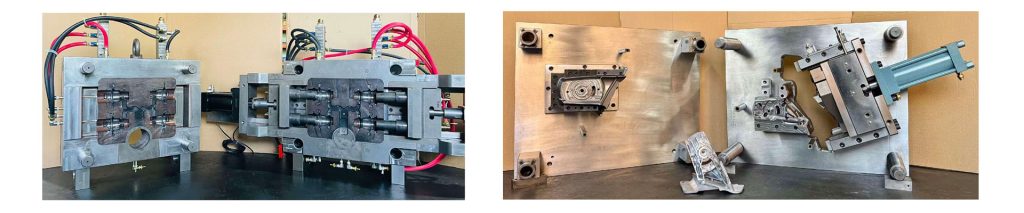

MOLDS & DIES

We bring products to market by facilitating relationships between our own workshop and our manufacturing partners and our clients. With our initial support, our clients can have their products manufactured at the highest quality and eventually take on the management of their individualized supply chain.

General Molds and Dies Services

Request for Quote / Schedule Development / First Article of Production / Development of Plastic Injection Molds, High/Low Pressure Die Casting Dies and Stamping Dies / Component Manufacturing / Quality Standards and Requirements

Tooling Development

ALPHA coordinates the tooling development for clients who choose to pursue production. We work hand in hand with our supply network to design, develop, and build durable tooling that will produce high quality components. Designing and manufacturing of plastic injection molds, high/low pressure die casting dies and stamping dies all managed by our engineering team and report to customers statue weekly until the first sampling day.

First Article of Production

We support our clients through the First Article of Production approval process, insuring quality and accuracy. The FAP approval process is a back and forth conversation between the factory, the client, and ALPHA that discusses imperfections and improvements that need to be made to tooling, parts, and assemblies before production begins.

Quality Control and Assurance

To insure the ongoing quality of parts, we provide our suppliers with quality control documents that outline the acceptable and unacceptable qualities of parts coming off the assembly line. During the product development process, we also audit our designs to help minimize any quality concerns we foresee and cater to our suppliers’ core capabilities.

PRODUCTION & ASSEMBLING

We bring products to market by facilitating relationships between our workshop and our manufacturing partners and our clients. With our initial support, our clients can have their products manufactured at the highest quality and eventually take on the management of their individualized supply chain.

General Production Services

Plastic Injection Molding / High Pressure Die Casting / Low Pressure Die Casting / Stamping / Surface Treatment and Finishing / Assembling

Plastic Injection Molding

Capability of injection molding from 120T, 280T, 360T, 500T, 750T, 800T, 1200T, 1500T, 2500T to 3000T.

Resin of production are PP, PS, ABS, PA-6, PA-66, PVC, HDPE, LDPE, TPE etc. and can be purchased easily in local

with datasheet which is confirmed with clients each time before sampling and molding. Quality reports like Weekly process report / FAI report / Molds sampling report / RMA report / 8D report / Process measuring / Shipping report/ Molds maintenance report all will be sent to customer during the process.

High / Low Pressure Die Casting

Capability of casting from 400T, 500T, 750T, 800T, 900T, 1250T, 1600T, 2000T, 2500t to 3000T

Stamping

Capability of stamping press from 40T to 800T

Surface Treatment and Finishing

Painting, plating, UV coating, anodize, matte, glossy, metallikon, crackle and aging.

Packaging Development

ALPHA has supplied clients with compact, structural, and sustainable packaging solutions. We optimize our designs for each product’s needs and unique distribution system, including online and retail sales. Although we don’t design graphics in-house, we work with local designers to create artwork for packaging.

Assembly and Pack Out

Our workers and network of suppliers is equipped to handle the assembly of complex goods, including electronic components, and pack out products for final shipping and delivery. Product manufacturing gets rolled together with packaging to output finalized, purchase-ready products, saving you time and energy.

SUPPLY CHAIN MANAGEMENT

Our supply chain spans across multiple countries and encompasses vendors who specialize in plastics manufacturing, metal fabrication, cut and sew, assembly and pack out, and distribution, among others capabilities. We source and organize vendors to help develop customized supply chains for our clients who choose to pursue production.

Our Network

We partner with production factories in the United States, Mexico, mainland China and Vietnam that range in size and capability, allowing for the perfect fit for each unique product. Our trusted network has the capabilities to carry out mass production efficiently and professionally providing the highest quality results. In addition, all of our suppliers are under Non-Compete and Non-Disclosure Agreements to insure the confidentiality of your product until release date.

Supplier Sourcing

Our vast network of suppliers covers most manufacturing capabilities. However, when new suppliers are needed, we source and vet multiple options before moving forward with a specific candidate. We look overseas and domestically to offer the best quality and pricing to our clients.

Overseas Project Management

Based in mainland China and HongKong, our overseas project managers provide on-site support for our clients’ products. Acting as your eyes on the factory floor, they can quickly address issues that pop up and insure quality before parts are sent to the clients’ countries.

Logistics and Transit

We utilize shipping partners to insure products get through customs at every border, keeping your product moving and on schedule. Our partners can streamline fulfillment of orders from factory to warehouse by different shipping terms like FOB, CIF, DDU or DDP.